A 3D printer with “eyes and brains” is being developed to print implants for regenerative medicine to repair damaged and/or lost body tissue.

- The addition of machine vision and artificial intelligence to fine tune medical 3D printers

- This will enable custom made tissue implants to suit the individual patient

- AI and machine learning would contribute to the ability to print heart valves and soft robotics

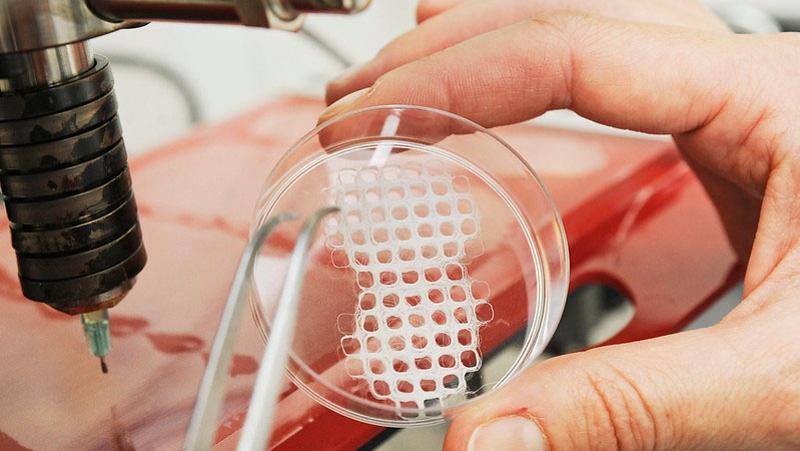

This scanning electron microscope (SEM) video above shows the complex three dimensional architecture of a tubular scaffold designed for tissue engineering applications.

An interdisciplinary study from bioengineers in QUT’s Centre in Transformative Biomimetics in Bioengineering, in collaboration with Professor Paul Dalton from Oregon University, has described the potential of artificial intelligence (AI) and machine vision in 3D-printers in the Advanced Materials Journal.

Centre director Distinguished Professor Dietmar W. Hutmacher said implants and medical devices such as scaffolds made with 3D printing could be custom made and patient specific.

“In contrast, implants and devices produced through traditional manufacturing methods are usually in standard sizes,” Professor Hutmacher said.

“However, we have several technical challenges to overcome before 3D printing transforms the advanced manufacturing of implants and medical devices.

“Commercially available 3D printers generally offer only high-speed, high-precision, or medical grade biomaterials and rarely do they offer all three.

“This limits their suitability as a manufacturing platform for medical devices such as biodegradable scaffolds for tissue engineering. The addition of AI and machine vision to 3D printing changes this paradigm.”

QUT biomedical engineers in collaboration with Professor Dalton are working to bring the benefits of 3D printing to a range of biodegradable medical device designs that have never been printed before such as heart valves, bone scaffolds, membranes for dental tissue engineering, and soft actuators (soft robotics) for minimal invasive surgery, Professor Hutmacher said.

“The team is accomplishing this by pairing its melt electrowriting (MEW) printer with machine-vision and machine-learning systems.

“The vision system comprehensively images the flight path of the extruded fibre to correct errors in real-time, while the machine-learning system uses that information to predict the fibre diameter of the scaffold and make more accurate final products.

“The processing of high-performance materials such as medical grade biomaterials for implants is very complex and requires fine tuning of all process parameters which is why we monitor the 3D printing process closely.

“By using AI, we can evaluate this data stream and identify hidden printing parameter relationships that are not recognizable to humans.

“This is precisely where the advantage of artificial intelligence lies: it is able to process very large volumes of data quickly, an assignment that is far too monotonous and hence difficult for the human brain.

“Adding machine vision and artificial intelligence (AI) gives the MEW printer the eyes and brains it has so far been missing.

“These new advancements have the potential to transform MEW printers which now will be able to additively manufacture medical devices and implants that have never been printed before.”

Convergence of machine vision and melt electrowriting was published in Advanced Materials.